Printing Methods

At Innov Enterprise, we help turn your ideas and design into realities with the various types of products and garments offerings that are suitable for heat transfer works to create customisation for your team and organization.

It is the process of combining heat with transfer paper to create a customized T-shirt or product. The primary materials used to transfer are heat transfer vinyl paper (coloured rubber material) and transfer paper (wax and pigment coated paper) and the use of heat (temperature depends on the transfer medium used and t-shirt design). The chosen logo, design, or image is printed onto a special transfer paper first, then heat-pressed onto the t-shirt.

They are widely used because it creates a heat-resistant and waterproof design on the fabric. It is one of the recommended printing methods when you need to print high-quality images that are high in resolution, multi colours tone images, as well as photo quality images. In addition, the colours created by the print image have high resolution and bright, eye-catching colours. The transfer paper has no restrictions on colour and design, it uses an inkjet printer to print images or artwork onto the transfer paper to create your unique design on the shirt or product. The other advantage is that it can print on low MOQ.

Adjust and resize the image to the actual print size required. The design will be printed onto a special transfer paper which can imprint sharp designs and images from the high resolution images provided.

After printing the image, place the into the plotter so that the machine can detect and cut the shape accordingly.

This is done using a weed tool to remove excess or unwanted parts of the print so that the print look just the way you want it to be on the shirt.

The following are some of the things that we consider before proceeding with the heat press process:

a) Temperature of heat press

The hot pressure temperature between 155’c and 180’c should be good. The optimal temperature depends on the transfer medium used and the type of shirt/fabric

b) Pressure used.

Typically, a medium pressure mode and contact is sufficient to transfer the print to the garment.

c) Make the apparel surface flat.

Place the garment or apparel on the heat press plate. Make sure that the apparel is placed directly on the board at the right position before printing. Double check that the pre-press apparel is placed flatly with no wrinkles or overlapping of the fabric as it affects the position of the print! Just like ironing your clothes, give the apparel a light press for about 2-3 seconds without printing to remove wrinkles that may affect the print.

d) Placement of the transfer paper

Place your printed and well cut transfer material (vinyl or transfer paper) onto your T-shirt. Check that the images are centralised and placed at the right position and angle before proceeding with the next step which is the heat press!

Do not press for too long as it may cause burn marks on the garment. Be sure to follow the instructions in your transfer paper in order to create a perfect masterpiece of your art on the garment or product.

e) Transferring the print onto the apparel/fabric

Once the print is ready to go, we begin to warm up the top layer of the heat press. Lift up the top layer once the timer is up, next, peel it with care and once that is done, The image is imprinted onto the apparel successfully.

Heat transfer is also effective if the image is printed onto objects, including cups, bags, plates, since the wax image can’t be washed off with water

Check out the other printing methods that we offer such as Direct-To-Garment (DTG) printing, Dye Sublimation, Heat Transfer, and Silk Screen Printing that you can consider to create your own original apparel or items for your company.

Need more information on the suitability of your logo to be imprinted onto the apparel for your school or business?

Contact us today via our hotline or send us an email at enquiry@innoventerprise.com and our friendly team will work on your request.

Create your own custom apparel with us today!

For the best optimal silk screen shirts result, other than having the required equipment and processes in place from our side, the next most important thing is to have high-resolution images. The images that you need to provide should be created and saved at a high resolution of between 150 to 300PPI (Pixels Per Inch) in various formats such as .PNG, .JPEG, .GIF, and BMP. Please refer to the table below for a preview of suitable files.

It should be in Vector Graphics or Hi-Resolution images with 300 PPI or above.

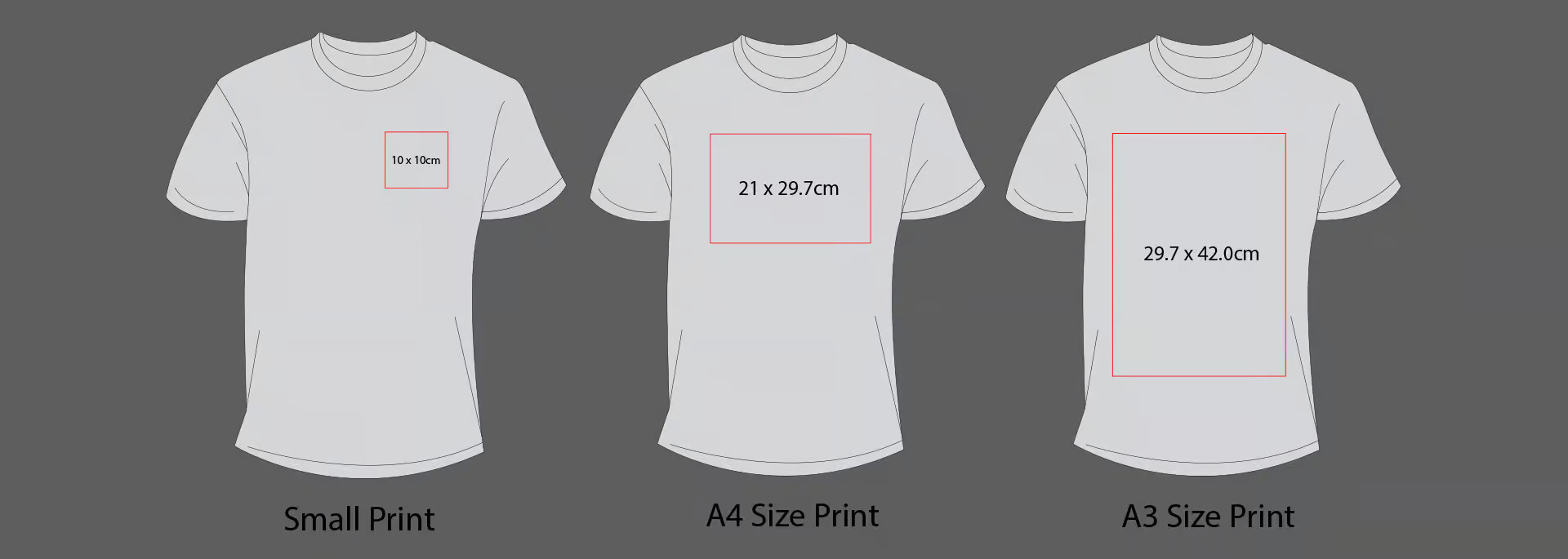

The printing size can be done as a small area over a pocket within 10cm x 10cm or used to print images that require covering a large area of Tee Shirts such as within A4 and A3 sizes.

Please note that the pricing is based on the print size within the dimension for easy calculation. We will indicate the actual dimension in the layout before the sample printing.

The pricing is determined based on the following attributes:

As the image or artwork is directly printed onto the transfer paper, it does not require MOQ of 30 pieces although the price will be significantly higher when you print less than 10 pieces.

Please refer to our online apparel catalogue for the ready-stock apparel for your selection that may suit you and your designs.

Typically, our turnaround time is within 2 weeks upon confirmation based on 50 to 100 pieces. However, if you need it sooner, please contact us and we will check with our production schedule on the feasibility to deliver within your requested timeline.